Feltronics

Step 0: Overview

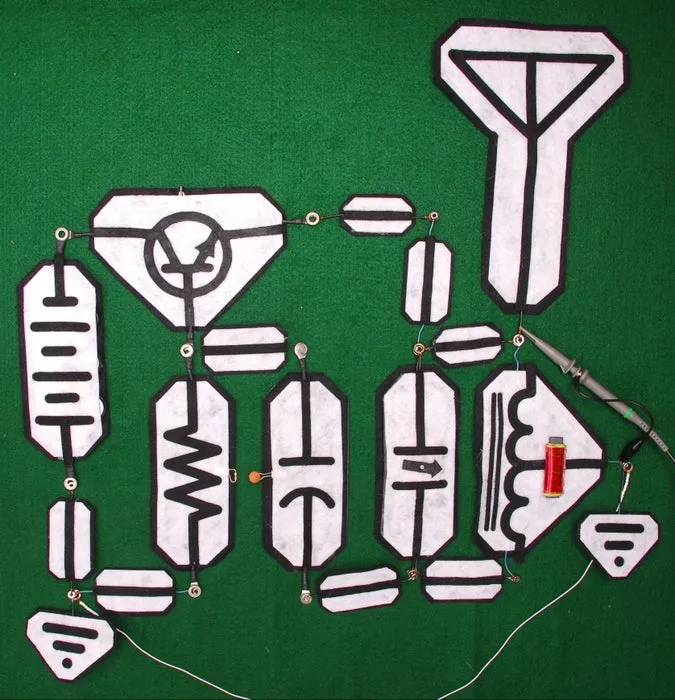

Feltronics turns your refrigerator into a soft circuit breadboard (a large-format electronics project kit). That is, you can make real, working electronic circuits and projects using big fuzzy felt pieces and stick them to metal surfaces. Hackerspace Charlotte took home the Grand Prize from the Global Hackerspace Challenge with this project in 2011. Here we present an easy method for creating your own set of fuzzy Feltronics. We also have a few videos from when we introduced Feltronics to the World which will address many more questions than we can in text.

This video is from a Tech Talk given at Skookum . It uses Feltronics to demonstrate the electronics in a simple radio:

These two videos demonstrate basic electronics to kids at the Discovery Place, a children's science museum in Charlotte, NC. We armed the kids with lasers and asked them to point out the path of electricity.

Discovery Place 2

This video shows an early demonstration of Feltronics at the 2011 Atlanta Mini Maker Faire. You can see the [not quite finished] RGB LED mixer circuit at 2 minutes and 4 seconds in (sorry, deep linking doesn't seem to work).

Step 1: Laser Cut the Pieces

- 4 x Outer Layers

- 1 x Battery Schematic Symbol

- 1 x Resistor Schematic Symbol

- 1 x Button Switch Schematic Symbol

- 1 x LED (Diode) Schematic Symbol

- 4 x Inner Layers.

Attachments

Step 2: Alternative to Laser Cutting

- 4 x Outer Layers

- 1 x Battery Schematic Symbol

- 1 x Resistor Schematic Symbol

- 1 x Button Switch Schematic Symbol

- 1 x LED (Diode) Schematic Symbol

- 4 x Inner Layers

Attachments

Step 3: Tools

Step 4: Parts List

The materials required to build a basic Feltronics component are:

- Black and White Felt (Laser Cut using these Templates - we recommend using a Laser Cutter)

- 24 g Stranded wire

- 3/16" Heat shrink

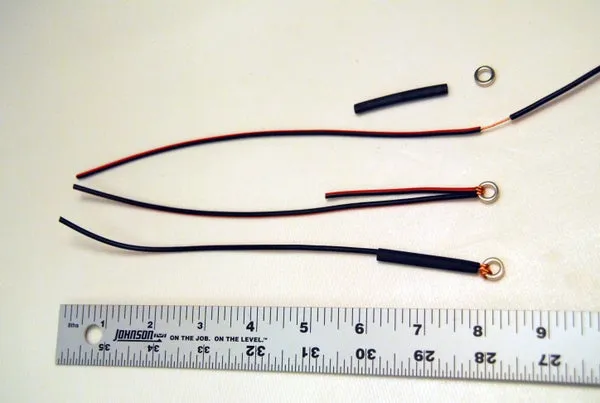

- 10 mm x 3 mm Ring Magnets

- Springs

- LED (or substitute your desired component)

- 1 Coin Batteries & Holder

- Momentary Button Switch

- 100 Ohm Resistor

The PDF template files are attached, so you can cut the templates by hand with scissors or on your laser (highly recommended). Most of the parts can be found on eBay such as the Extension Springs - Stainless . Other parts like the ring magnets can be found with reasonable prices on sites like K&J Magnetics or Super Magnet Man and others. Felt is readily available for your local fabric store, but don't get the little rectangles, buy the yard, it is far more economical. If you shop carefully, the cost per part should be less than $1

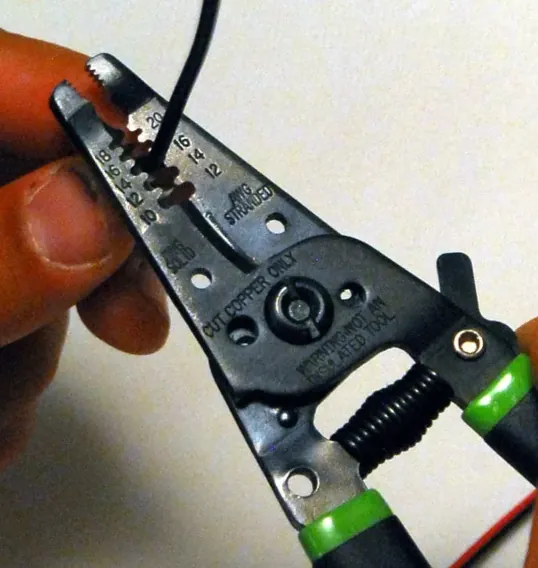

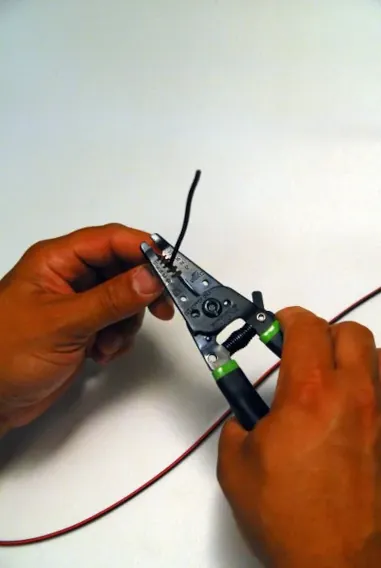

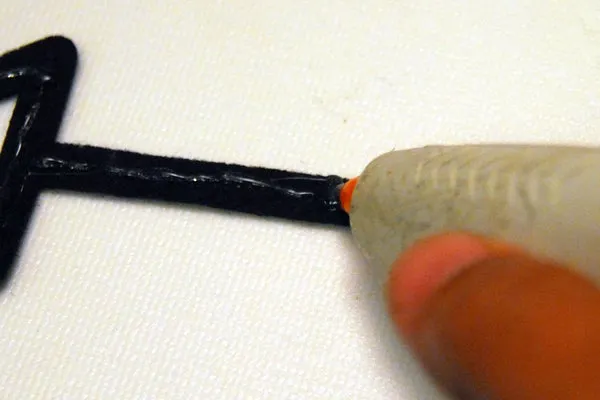

Step 5: Strip Wire Leads

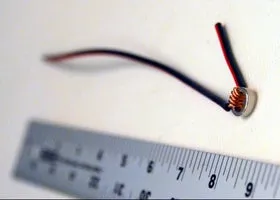

- Cut a single piece of 24 gauge stranded wire approximately 8 inches in length.

- Strip 3 inches of insulation off one end, exposing about an inch of bare wire. We recommend leaving the extra insulation on the wire as this will provide extra structural support .

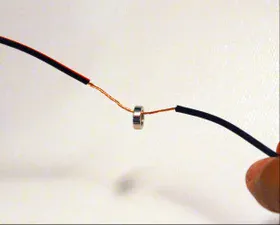

Step 6: Attach the Magnet to the Wire

Step 7: Add Heat Shrink

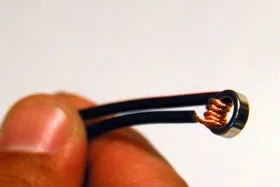

- Slide 2 inches of 3/16" heat shrink tubing over the long and short wire ends.

- Heat the wire with a hot air gun, soldering iron, or even the tip of a hot glue gun .

- Be careful not to heat up the Magnet !! The magnet will be degaussed if it gets too hot.

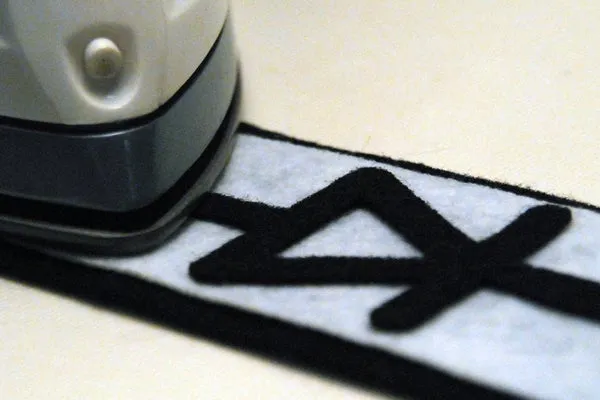

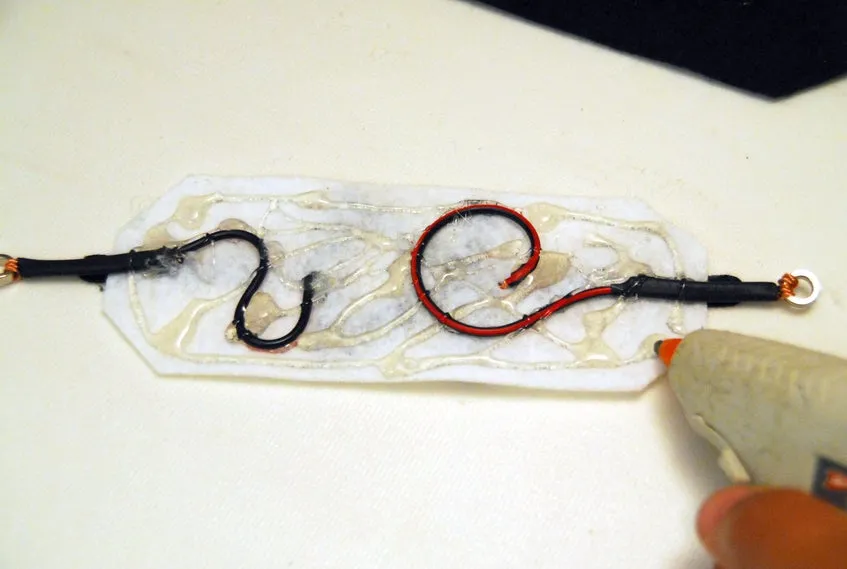

Step 8: Glue Schematic Symbol

- Apply hot glue to the feltronics schematic symbol

- Avoid putting glue into the laser cut holes for the wires

- Flip the symbol over and onto the white felt piece

- Line up the wire holes in the top layer (octogon)

- Avoid smushing glue into the laser cut holes for the wires

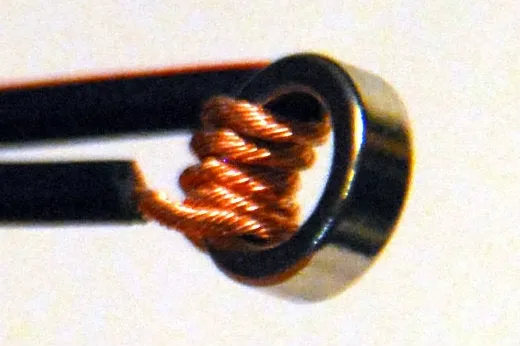

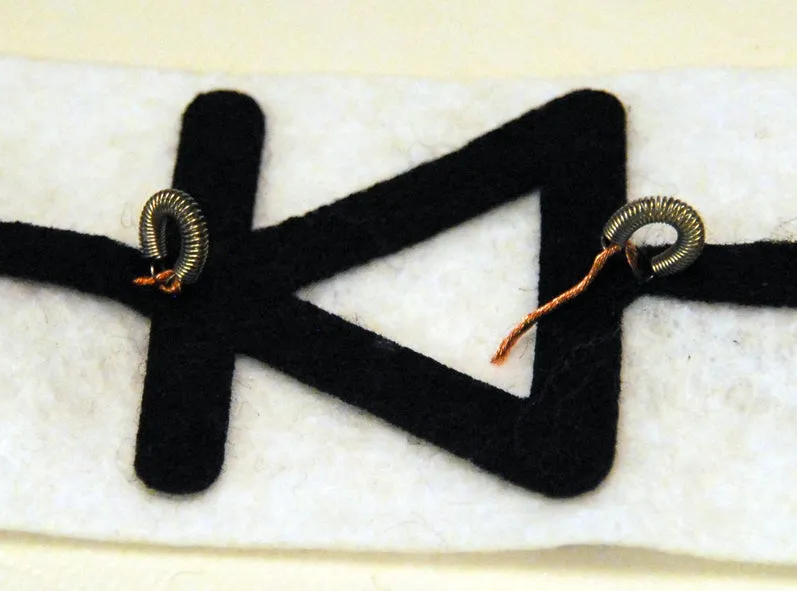

Step 9: Attach Spring Terminal

- Strip 3/4 inch of insulation off the other end of the Wire and insert the wire through the top felt piece.

- Bend the spring in half so the end loops are next to each other.

- Thread the stripped wire through the spring loops .

- Bend the wire and twist it around itself to hold the springs .

Step 10: Final Assembly

Step 11: Make a Circuit and Other Connector Ideas

You can make circuits big and small, simple or complex with Feltronics. All you have to do is make more pieces for your electronics project kit, and you're on your way. If there is a new schematic symbol that isn't in your kit, just cut one out.

Example Circuits

A few of the circuits we've made so far:

- Simple series circuits (analog 'AND' logic)

- Simple parallel circuits (analog 'OR' logic)

- Complex series and parallel circuits (AND with OR in various configurations)

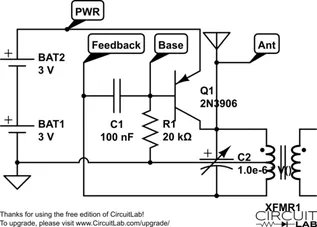

- AM Radio (with only five components!!)

- FM Radio (with a few more)

- Flip Flops (a-stable multivibrator)

- Analog Multi-meter (Analog to Digital to Servo Control) with an Arduino

- RGB LED mixer

- And endless more

Alternative Connector Ideas

We have also evolved our manufacturing process over time. Presented here are several iterations and possibilities for connecting the components:

- Magnets in the middle of parts for connectors with washers on component leads

- Magnets in the middle of parts for connectors with magnets on component leads

- Magnets in the middle of parts for connectors with component leads sandwiched between magnets

- Washers in the middle with magnets on component leads

- Sockets in the middle with components plugged in

- Alligator clips in the middle holding onto component leads

- Foil tape (HVAC tape) wrapped [regular] magnets

- Springs in the middle with component leads poking through (as used in this instructable)

- Header type connector on the side of the Feltronics piece with components sticking in (for mass production if we ever get a laser - hint, hint)

- And surely a few others that I've forgotten.

Please share your designs and ideas with others. We'll post more schematics and templates just as soon as we clean them up.